#025: Production of Soy Sauce

There are two ways to make soy sauce: the traditional brewing process or the modern chemical hydrolysis process. In short, the traditional process involves the fermentation of soybeans and wheat by fungi and some bacteria. The hydrolysis process extracts the amino acids from soy and adds other ingredients to create a liquid similar to soy sauce.

Traditional production of soy sauce involves three steps: koji-making, brine fermentation, and refinement.

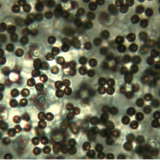

- Koji-Making: First the soybeans are mashed and boiled and the wheat is roasted and crushed. The cooked soybeans and wheat are then blended together, usually in equal parts. Then a seed mold (either Aspergillus oryzae or Aspergillus soyae) is added to the cooked soybean/ wheat mixture. This mixture is left to ferment for three days in large, perforated vats. The perforations allow air to circulate, creating ideal conditions for mold growth. The resulting mixture is known as “koji.”

- Brine Fermentation: The koji is then moved to fermentation tanks. There, it is mixed with water, salt, and other fermenters (specific yeasts and lactic acid bacteria). This mash is called “moromi.” During the several months required for brine fermentation, the microorganisms produce ethanol and a wide variety of flavor compounds. The moromi is eventually turned into a reddish-brown semi-liquid known as “mature mash.”

- Refinement: The soy sauce is separated from the solid soy and wheat remains by passing it through a number of filtration cloths. The resulting liquid is pasteurized, bottled, and sold.

There are many ways this process can be tweaked to produce different flavors, but they all follow the three steps above.

The hydrolysis process has two main benefits over the brewing process: it takes much less time (three days instead of several months) and it has a longer shelf life. In this process, the soy beans are broken down into amino acids by being boiled in HCl. Then the amino acids are neutralized by sodium carbonate, filtered, mixed with active carbon, and purified by filtration to produce hydrolyzed vegetable protein. Color, corn syrup, and salt are then added to give it a soy sauce color and texture. However, this process is a very simplified version of the natural brewing process, so the end result lacks many of the extra organic compounds that give the brewed soy sauce a desirable taste.

See Further:

http://www.madehow.com/Volume-3/Soy-Sauce.html

http://www.kikkomanusa.com/foodservice/soysaucebasics/artofnaturalbrewing.php

http://en.wikipedia.org/wiki/Soy_sauce

http://www.soyinfocenter.com/HSS/soy_sauce1.php (I did not use this site for any information above, but have included it for those of you who might be interested in the history of soy sauce)

![#011: Characteristics of Kingdom Fungi [Archived]](https://www.fungusfactfriday.com/wp-content/themes/hueman/assets/front/img/thumb-small-empty.png)