#024: Fungi in the Production of Chocolate

Along with red roses and cheesy cards, chocolate is one of the common Valentine’s Day gifts. So on this day when heart-shaped boxes of chocolates are a common sight, I thought you might like to learn a little about how chocolate gets from the cocoa beans to the cloying boxes (be thankful I didn’t decide to discuss fungal diseases you can get from roses). You probably already know that chocolate comes from the seeds of the cacao tree, Theobroma cacao. The first way in which fungi allow for the production of chocolate is by helping the cacao tree to grow. In order to get nutrients required for growth, all trees participate in mutualistic relationships with fungi called mycorrhizae. There are a number of types of mycorrhizae, but Theobroma cacao only forms endomycorrhize. In these mycorrhize, fungi in the phylum Glomeromycota penetrate the root cells of the tree and form specialized structures that facilitate nutrient exchange. The fungus takes sugars from the tree but in return gives up hard-to-get nutrients like phosphorous. In case you were wondering, the glomeromycota do not produce mushrooms.

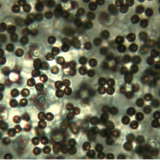

Fungi take a much more active role later on in chocolate production. Once the tree is big enough, it starts to flower and produce seed pods. The flowers are positioned flush with the trunk and larger branches, which allows the tree to support the large cacao pods. Once ripe, the pods are gently cut off the side of the tree and the seeds are taken out of the pods. It may surprise you to learn that these pods are impossible to eat! They are much too bitter for animals or humans to be interested in eating them. The seed coat, however, is pulpy and sweet. Animals will eat the seed coat and discard the bitter seeds, thus dispersing the seeds. Humans, however, discovered that the rotten cacao seeds were tasty. In fact, it is fungi that are responsible for turning the inedible seeds into the beginnings of the world’s favorite delicacy. The yeast Candida krusei and a yeast-like Geotrichum sp. are the two fungi that ferment the cacao beans. The Geotrichum is yeast-like because it has hyphae that break up into individual cells. As of 2007, the exact species of Geotrichum that is involved in chocolate-making is not known well enough to receive a scientific name (thus the “sp.” instead of a species name). These fungi are present in the environment, but companies often add specific strains that result in a particular flavor. Once the beans are removed from the pods they are piled into boxes and allowed to ferment for a few days. The fungi ferment the sugars in the pulp, releasing ethanol and heat. Bacteria break down ethanol into lactic acid and acetic acid and heat. The heat and acetic acid kill the seeds by the second day, which results in the breakdown of cell walls and a number of complex chemical reactions that result in chocolate’s distinctive flavor and aroma. The piles of beans are stirred during this time to ensure even fermentation of the beans. The extra acids and pulp drain off, leaving the now-desirable beans. The beans are then dried and shipped to manufacturers.

The rest of the chocolate-making process is up to the chocolate manufacturer. The beans are first roasted to bring out the chocolate flavor. Then the outer shell of the bean is removed and the remaining meat (in pieces called “nibs”) is sorted by size. The nibs are then ground into a liquid known as “cocoa liquor” (no, there’s no alcohol in it). The cocoa liquor is then pressed to separate the cocoa butter from the solids. The remaining solids are known as “cocoa presscake.” The cocoa presscake is then ground to make cocoa powder. In order to make chocolate, cocoa butter is added to chocolate liquor along with sugar, milk, and other ingredients, depending on the type of chocolate. The chocolate is then pressed through a series of rollers to refine the texture. This is followed by a conching or emulsifying process that further enhances the flavor and texture. The chocolate is then heated, cooled, and reheated to prevent crystallization. The chocolate is then molded, packaged, and sold.

So next time you give someone a gift of chocolate, say a little thank you to Theobroma cacao and fungi. Happy Valentine’s Day from Fungus Fact Friday!

See Further:

http://www.icco.org/about-cocoa/harvesting-and-post-harvest.html

http://www.icco.org/about-cocoa/processing-cocoa.html

http://botit.botany.wisc.edu/toms_fungi/feb2006.html

http://www.sfu.ca/geog351fall03/groups-webpages/gp8/prod/prod.html

You can also get more details from any number of chocolate manufacturers’ websites.

![#049: Coffee Rust [Archived]](https://www.fungusfactfriday.com/wp-content/themes/hueman/assets/front/img/thumb-medium-empty.png)

![#011: Characteristics of Kingdom Fungi [Archived]](https://www.fungusfactfriday.com/wp-content/themes/hueman/assets/front/img/thumb-small-empty.png)

1 Response

[…] If you’re interested in the production of chocolate, see FFF#024. […]